How Do You Calculate Cycle Time

Treneri

Apr 07, 2025 · 6 min read

Table of Contents

How Do You Calculate Cycle Time? A Comprehensive Guide

Cycle time is a crucial metric in various fields, from manufacturing and project management to software development and customer service. Understanding how to calculate and optimize cycle time is essential for boosting efficiency and improving overall performance. This comprehensive guide will delve into the intricacies of cycle time calculation, exploring different methods, applications, and strategies for improvement.

What is Cycle Time?

Cycle time refers to the total time it takes to complete a process, from start to finish. This encompasses all steps involved, including waiting periods, processing time, and any delays. It's a critical indicator of efficiency and productivity, offering insights into bottlenecks and areas for improvement. Unlike lead time (which includes waiting for external factors), cycle time focuses solely on the internal processes within a system.

Key Components of Cycle Time Calculation

Accurately calculating cycle time requires a thorough understanding of its components. While the specific steps may vary depending on the context, the fundamental elements remain consistent:

1. Identifying the Process: Defining Start and End Points

The first step is clearly defining the process you're measuring. What are the specific activities involved, and what constitutes the beginning and end of the process? For instance, in manufacturing, this could be the time from raw materials entering the production line until the finished product leaves. In software development, it might be the time from receiving a feature request to deploying the finished code. Ambiguity here can significantly skew your results.

2. Data Collection: Tracking Time and Activities

Accurate data is paramount. You'll need a reliable method to track the time spent on each stage of the process. This could involve:

- Time Tracking Software: Tools designed to monitor time spent on specific tasks.

- Spreadsheets: Simple yet effective for smaller processes.

- Manual Tracking: Writing down start and end times for each stage. This is prone to errors and should only be used for smaller, simpler processes.

- Process Mapping: Visually representing the process flow, which helps identify all steps and potential bottlenecks.

Regardless of the method, ensuring data accuracy is vital. Inconsistent or missing data can lead to misleading conclusions.

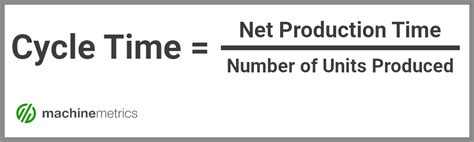

3. Calculating Total Cycle Time

Once you have collected the necessary data, calculating the cycle time is straightforward: simply add up the time spent on each stage of the process. For example, if a process has three stages:

- Stage 1: 2 hours

- Stage 2: 1.5 hours

- Stage 3: 0.5 hours

The total cycle time would be 2 + 1.5 + 0.5 = 4 hours.

Different Methods for Calculating Cycle Time

The basic addition method works well for straightforward processes. However, more complex scenarios may require alternative approaches:

1. Time-Motion Studies: Detailed Analysis

This method involves meticulously observing and recording the time spent on each step of a process. It's particularly useful for identifying inefficiencies and optimizing workflows. This approach is highly detailed and resource-intensive but provides incredibly granular data.

2. Value Stream Mapping: Identifying Waste

Value stream mapping visually illustrates all steps in a process, highlighting value-added and non-value-added activities (waste). By pinpointing waste, you can focus on reducing cycle time by eliminating unnecessary steps.

3. Statistical Process Control (SPC): Monitoring Variability

SPC techniques, such as control charts, help monitor cycle time variations over time. This allows you to identify patterns and trends, enabling proactive adjustments to maintain consistent cycle times.

Applications of Cycle Time Calculation

Cycle time calculation isn't confined to a single industry. It finds applications across diverse sectors:

1. Manufacturing: Optimizing Production Lines

In manufacturing, cycle time is critical for optimizing production lines, reducing waste, and meeting deadlines. Tracking cycle time for each stage reveals bottlenecks and areas for improvement.

2. Project Management: Meeting Deadlines and Managing Resources

Project managers use cycle time to track project progress, identify potential delays, and manage resources effectively. Shortening cycle times ensures projects are completed on time and within budget.

3. Software Development: Agile Methodologies

Agile development relies heavily on cycle time measurements, particularly in sprints. Tracking the time it takes to complete tasks helps teams assess their velocity and improve their efficiency.

4. Customer Service: Improving Response Times

In customer service, cycle time is a key metric for evaluating response times and customer satisfaction. Reducing cycle time leads to improved customer experience and loyalty.

5. Healthcare: Streamlining Processes and Improving Patient Care

Healthcare providers use cycle time to analyze patient flow, optimize processes, and improve patient care. Reducing wait times and streamlining procedures improves patient outcomes.

Optimizing Cycle Time: Strategies for Improvement

Once you have calculated your cycle time, the next step is to find ways to improve it. Here are some effective strategies:

1. Identify Bottlenecks: Pinpointing Constraints

The first step is to identify bottlenecks – stages of the process that significantly slow down overall cycle time. These can be identified through process mapping, data analysis, or direct observation.

2. Streamline Processes: Eliminating Waste

Once bottlenecks are identified, focus on streamlining the process to eliminate unnecessary steps or delays. This could involve automation, process simplification, or improved workflow.

3. Improve Employee Training: Enhancing Skills and Efficiency

Investing in employee training can significantly improve efficiency. Better-trained employees are faster, make fewer mistakes, and require less supervision.

4. Invest in Technology: Automating Tasks and Improving Communication

Technology can automate repetitive tasks, improve data flow, and facilitate better communication between teams, all of which contribute to reduced cycle times.

5. Implement Lean Principles: Reducing Waste and Improving Flow

Lean principles focus on eliminating waste in all its forms. Applying lean methodologies can significantly reduce cycle time and improve overall efficiency.

6. Continuous Improvement: Monitoring and Adjusting

Cycle time improvement is an ongoing process. Regular monitoring and adjustment are crucial for maintaining improvements and adapting to changing conditions. Using tools like Kaizen (continuous improvement) events can foster a culture of improvement.

Cycle Time vs. Lead Time: Key Differences

It's important to distinguish between cycle time and lead time. While both relate to the time it takes to complete a process, they differ significantly:

- Cycle Time: Focuses solely on the internal processing time within a system. It excludes waiting times for external factors.

- Lead Time: Includes all time, including internal processing and waiting time for external factors like supplier deliveries or customer approvals.

Understanding this distinction is vital for accurate analysis and effective improvement strategies.

Advanced Cycle Time Calculations and Considerations

For highly complex processes, more advanced calculations and considerations may be necessary:

- Little's Law: Relates average inventory, throughput rate, and average cycle time. This law can be useful in predicting cycle time based on other known parameters.

- Queuing Theory: Analyzes waiting times in systems with queues. This is particularly relevant when bottlenecks cause significant waiting times.

- Simulation Modeling: Allows for modeling various scenarios and predicting cycle time under different conditions. This can help in evaluating the impact of different improvement strategies before implementation.

Conclusion

Calculating cycle time is a vital process for improving efficiency and productivity across various industries. By understanding its components, employing appropriate calculation methods, and implementing effective optimization strategies, organizations can significantly enhance their performance and gain a competitive edge. Remember that continuous monitoring and improvement are key to long-term success in cycle time reduction. The journey towards optimized cycle times is a continuous process of refinement and adaptation.

Latest Posts

Latest Posts

-

What Grade Is A 19 Out Of 25

Apr 08, 2025

-

How Many Balloons To Lift A Pound

Apr 08, 2025

-

How Many Months Is 66 Days

Apr 08, 2025

-

How Many Miles In 12000 Feet

Apr 08, 2025

-

How Much Concrete To Fill 8x8x16 Block Per

Apr 08, 2025

Related Post

Thank you for visiting our website which covers about How Do You Calculate Cycle Time . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.