How To Calculate Board Feet For Lumber

Treneri

Apr 06, 2025 · 6 min read

Table of Contents

How to Calculate Board Feet for Lumber: A Comprehensive Guide

Buying lumber can be confusing, especially when dealing with different sizes and the often-misunderstood unit of measurement: the board foot. Understanding board feet is crucial for accurate lumber purchasing, ensuring you get the right amount of wood for your project and avoid costly mistakes. This comprehensive guide will walk you through everything you need to know about calculating board feet, from the basics to more complex scenarios.

Understanding Board Feet: The Basics

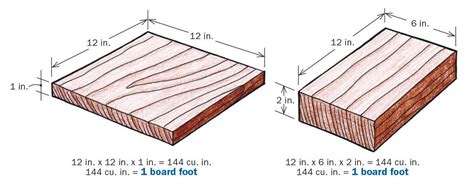

A board foot (bf) is a unit of measurement for lumber volume, equivalent to a board 1 inch thick, 12 inches wide, and 12 inches long (144 cubic inches). It's a standard unit used in the lumber industry, regardless of the actual dimensions of the board. Think of it as a standardized unit for comparing lumber volume, much like using gallons to compare liquid volume.

Why use board feet? Board feet provide a consistent way to compare the amount of lumber in different sizes. A 2x4x8 and a 1x6x16, while having different dimensions, can actually contain the same volume in board feet. Using board feet simplifies the calculation of lumber needed for a project, especially when dealing with various sizes of lumber.

Calculating Board Feet: The Formula

The basic formula for calculating board feet is straightforward:

Board Feet = (Thickness in inches) x (Width in inches) x (Length in inches) / 144

Let's break it down:

-

Thickness: This is the nominal thickness of the board, not the actual thickness. Nominal sizes (e.g., a 2x4) are different from actual dimensions (a 2x4 is actually closer to 1.5" x 3.5"). Always use nominal dimensions when calculating board feet.

-

Width: This is the nominal width of the board in inches. Again, use the nominal size, not the actual measurement.

-

Length: This is the length of the board in inches.

-

144: This is the number of cubic inches in a board foot.

Example 1: Calculating Board Feet for a 2x4x8

Let's calculate the board feet for a standard 2x4 that's 8 feet long.

-

Convert feet to inches: 8 feet * 12 inches/foot = 96 inches

-

Apply the formula: (2 inches) x (4 inches) x (96 inches) / 144 = 5.33 board feet

Therefore, a single 2x4x8 contains approximately 5.33 board feet.

Example 2: Calculating Board Feet for a 1x6x12

Let's calculate the board feet for a 1x6 board that's 12 feet long.

-

Convert feet to inches: 12 feet * 12 inches/foot = 144 inches

-

Apply the formula: (1 inch) x (6 inches) x (144 inches) / 144 = 6 board feet

This shows that a 1x6x12 contains 6 board feet. Notice that this is the same volume as two 1x6x6 boards.

Dealing with Different Lumber Sizes

The formula remains the same regardless of the lumber size. Here are a few more examples to illustrate:

Example 3: A 4x4x10:

(4 inches) x (4 inches) x (120 inches) / 144 = 13.33 board feet

Example 4: A 1x12x16:

(1 inch) x (12 inches) x (192 inches) / 144 = 16 board feet

Example 5: A 2x6x14:

(2 inches) x (6 inches) x (168 inches) / 144 = 14 board feet

Calculating Board Feet for Irregularly Shaped Lumber

Calculating board feet for irregularly shaped lumber requires a slightly different approach. You'll need to estimate the volume of the wood. One common method involves breaking down the irregular shape into smaller, more manageable rectangular shapes, calculating the board feet for each, and then summing up the results. This approach provides a reasonable estimate.

Tips for Accurate Lumber Calculation

-

Use Nominal Dimensions: Always use the nominal dimensions (the stated size) of the lumber when calculating board feet, not the actual dimensions.

-

Account for Waste: Factor in potential waste due to cutting, imperfections, or mistakes. It's always better to have a little extra lumber than to run short during your project. Adding a 10-15% buffer is a good starting point, but this may vary depending on the complexity of your project.

-

Check with Your Supplier: Consult with your lumber supplier; they can help you determine the exact amount of lumber you need for your specific project, considering potential waste and any special cutting needs.

-

Round Up: When dealing with fractions of a board foot, it's best to round up to the nearest whole board foot to ensure you have enough material.

-

Use a Calculator: While the formula is simple, using a calculator can help you avoid errors, especially when dealing with multiple pieces of lumber. Many online calculators are available to assist with the calculation.

Beyond Board Feet: Understanding Other Lumber Measurements

While board feet are the standard for lumber volume, other measurements are also important:

-

Linear Feet: This measures the length of the lumber in feet. It's useful when planning layout but doesn't account for the cross-sectional area.

-

Cubic Feet: This measures the total volume of the lumber in cubic feet. While related to board feet, it's less commonly used in the lumber industry. Converting cubic feet to board feet requires understanding the dimensions and applying a conversion factor.

-

Actual Dimensions: These are the precise dimensions of the lumber, typically slightly smaller than the nominal dimensions due to planing and milling processes. This is rarely used for calculating board feet but is crucial for precise joinery and fitting.

Advanced Applications: Estimating Lumber for Complex Projects

For complex projects involving multiple lumber sizes and shapes, creating a detailed lumber list is essential. This list should specify:

- Type of Lumber: (e.g., pine, oak, cedar)

- Dimensions: (e.g., 2x4, 1x6, 4x4)

- Length: (e.g., 8 feet, 12 feet, 16 feet)

- Quantity: (e.g., 10 pieces, 25 pieces)

- Calculated Board Feet: (for each item in the list)

Sum the board feet for all items to determine the total amount of lumber needed. Remember to account for waste. Using a spreadsheet can greatly simplify this process, allowing you to easily track and adjust quantities as needed.

Troubleshooting Common Mistakes

-

Using Actual Dimensions: Remember to always use nominal dimensions in your calculations.

-

Incorrect Unit Conversions: Double-check that all measurements are in inches before applying the formula.

-

Forgetting to Divide by 144: Don't forget this crucial step in the formula!

-

Underestimating Waste: Always add a buffer for waste; it's better to have extra lumber than to fall short.

Conclusion: Mastering Board Feet Calculation

Mastering the art of calculating board feet is a crucial skill for anyone working with lumber. By understanding the basic formula and applying the tips and techniques outlined in this guide, you can accurately estimate the amount of lumber needed for your projects, saving you time, money, and frustration. Remember to always double-check your calculations and account for potential waste. With practice, calculating board feet will become second nature, empowering you to confidently tackle your next woodworking endeavor.

Latest Posts

Latest Posts

-

This Produces All Possible Combinations Of Factors

Apr 07, 2025

-

How To Add Time And A Half

Apr 07, 2025

-

How Many Miles Is 8000 Feet

Apr 07, 2025

-

180 Libras A Kilos Cuanto Es

Apr 07, 2025

-

How Much Years Is 1000 Days

Apr 07, 2025

Related Post

Thank you for visiting our website which covers about How To Calculate Board Feet For Lumber . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.